To estimate the cost and Return on Investment (ROI) of a complete presswood pallet production line with two press machines, we can look at several key factors based on available information:

Cost of Setup:

- Machinery Costs:

- The cost of each press machine can vary significantly based on brand, capacity, and features. From available sources, presswood pallet machines can range from tens of thousands to hundreds of thousands of dollars per unit. Given the lack of specific pricing for a two-machine setup, we can infer from general equipment costs:

- A basic presswood pallet machine might start around $50,000 to $100,000 each.

- Advanced or larger models could exceed this range, potentially going into the hundreds of thousands for each machine.

- Additional Equipment:

- Wood Chipping Machine: Essential for preparing raw materials, estimated costs can be in the range of $10,000 to $50,000.

- Wood Crusher Machine: For further processing, similar cost range as the chipper.

- Drying Machine: Important for moisture control, prices can start from $20,000 for smaller units to well over $100,000 for industrial ones.

- Glue Mixing Machine: For binding materials, around $5,000 to $20,000.

- Miscellaneous: Conveyors, dust collectors, and other auxiliary equipment might add another $10,000 to $50,000 or more.

- Installation, Training, and Infrastructure:

- Installation and setup can add another 10-30% to equipment costs.

- Training for staff or hiring skilled labor.

- Possible modifications to your facility for space, power, or safety.

- Total Initial Investment:

- Based on the above, a rough estimate for a complete setup with two press machines might fall between $200,000 to $600,000 or more, depending on the specifics of each component.

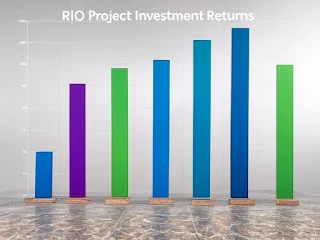

Return on Investment (ROI):

- Production Capacity:

- Two press machines could potentially double the output compared to one. If one machine can produce around 300 pallets per day (as an example from a case study), two could theoretically produce up to 600 pallets daily, depending on hours of operation and efficiency.

- Selling Price of Pallets:

- Presswood pallets have been noted to start at around $7.00 per unit for standard sizes (48”x 40”), but prices can vary based on size, customization, and market demand.

- Operational Costs:

- Include labor, raw materials, utilities (like electricity for machines), maintenance, and overheads like rent or mortgage payments on the facility.

- Revenue Calculation:

- If selling at $7 per pallet and producing 600 pallets a day for 250 working days a year, the annual revenue could be:

- 600 pallets/day * $7/pallet * 250 days/year = $1,050,000/year.

- ROI Calculation:

- Assuming the setup cost is around $400,000 (mid-range estimate):

- Net profit needs to account for costs like raw materials, labor, etc. Let's say operational costs consume half of the revenue for simplicity:

- Net profit = $1,050,000 - $525,000 (operational costs) = $525,000/year.

- ROI Timeframe:

- Initial Investment / Net Annual Profit = $400,000 / $525,000 ≈ 0.76 years or about 9 months to break even, assuming consistent operation and sales.

Notes:

- These figures are speculative based on general market data and should be validated with market-specific information, detailed cost analysis, and actual production data.

- ROI can be significantly impacted by market conditions, competition, raw material costs, and production efficiency.

For precise costs and ROI, consulting with manufacturers like Palletsbiz.com, who provide such equipment, would be beneficial as they can offer more tailored information based on specific needs and local market conditions.

Comments

Post a Comment